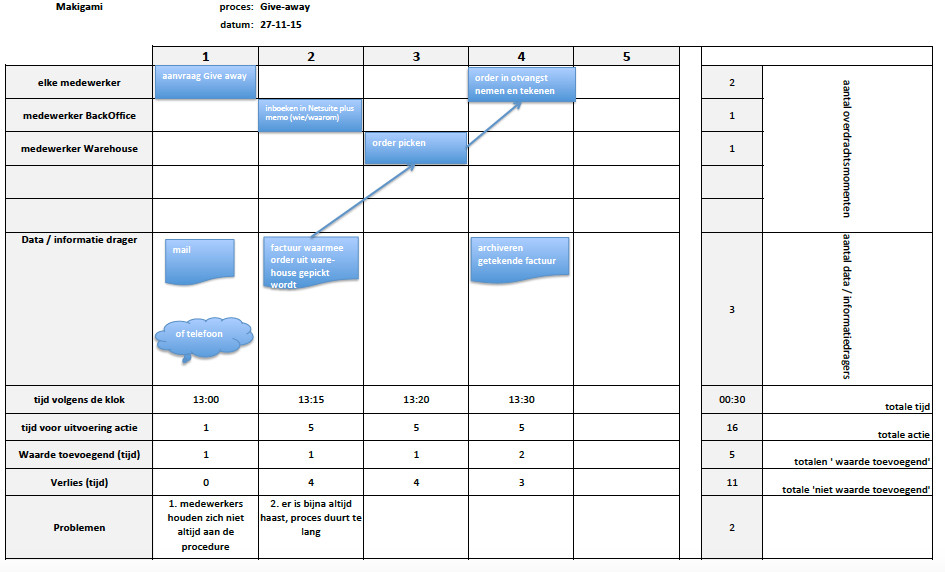

Essentially a form of process map, it contains “the Golden Rules” which consist of the following 5 factors:

- Activities performed by all participants

- All documents/media used for communication

- Communication

- Time-analysis

- Identified problems

As a process map, Makigami focuses on visualising aspects of the organisation which are not physical or directly visible. The Makigami Process Map also can be used to improve the investigated process by designing a future state map after taking away the identified losses.

This process maps shows:

- Wrong information

- Waiting for data

- Check data

- Rework

- Storing

- Moving

At the end makigami should give an overview about the non visable processes of the organisation.

Makigami contains 3 phases:

- What is the actual condition now?

- What is the target condition?

- What steps have to be done to reach the target condition?